| Asset Management |

Case Study: Management of injection casting mold

| Object | Injection Casting Mold |

| Temperature | 200~400℃ x several hours x multiple cycles |

| Products | HP-120S HP-150N HP-350N |

Customer’s request

- Eliminate problems caused by poorly identified casting molds

- Use barcode identification which will survive multiple heat cycles

- Scan to verify mold identification at each process

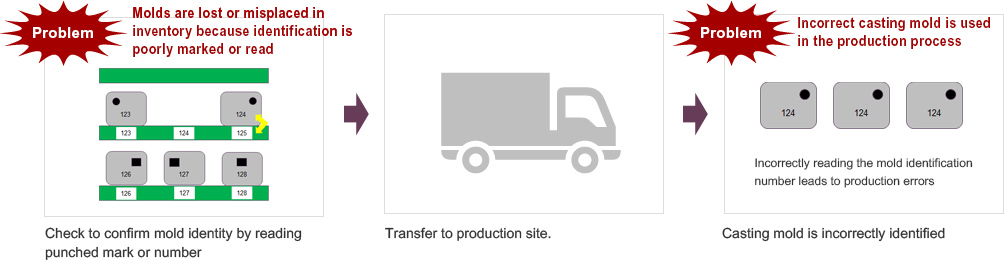

Initial Process Management

Visual inspection of stamp marking to confirm identification

Process Issues

- Mold identification errors occur because of poor marking methods

- Mold identification degrades after multiple processes leading to identification errors

- Production issues occur because of misidentified molds

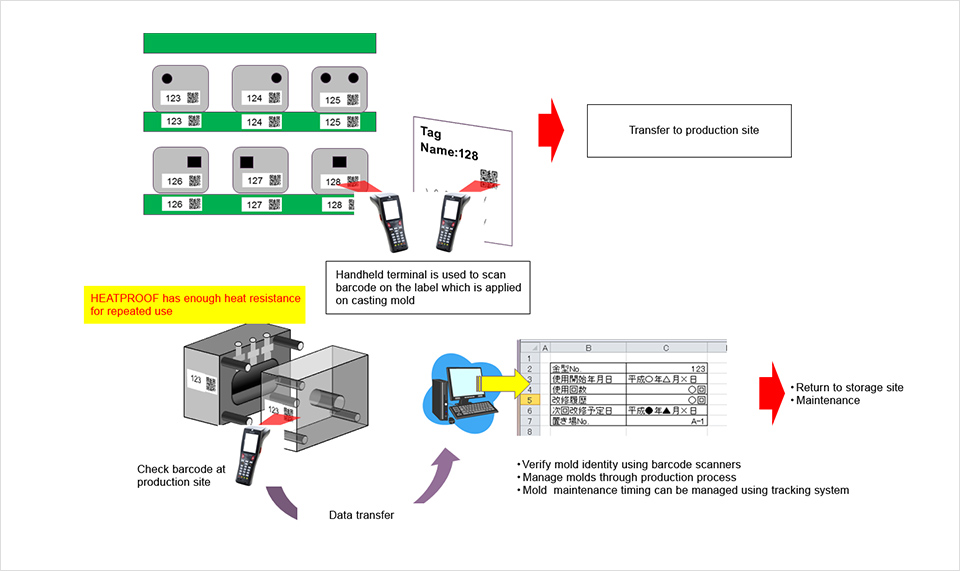

HEATPROOF Solution

| 1 | Provide heat resistant identification which can survive multiple cycles |

| 2 | Introduce a barcoding system which will allow molds to be verified by scanners |

| 3 | Provide mold identification which will survive outdoor exposure. |

| 4 | Eliminate the misidentification of molds caused by human error |

| 5 | Improve the mold tracking system through the production process |