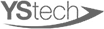

Heat resistant labels for annealing, homogenizing and other reheat processes

YStech can support in barcode identification solutions for heat resistant process management using HEATPROOF labels and tags. Uses include metals, ceramics, electronics, and automotive industry parts and processes, as well as asset and tooling management.

Lineup

HP-120S

- Application temperature from room temp to 220℃

- Maximum heat resistance to 220℃.

- Chemical reistance

- Strong initial adhesion

- Excellent ink stability and resistance to smudging at higher application temperatures

HP-120SH4

- Application temperature from room temp to 220℃

- Maximum heat resistance to 220℃.

- Higher Chemical reistance than HP-120S

- Stronger initial adhesion than HP-120S

- Excellent ink stability and resistance to smudging at higher application temperatures

HP-ST200

- Maximum heat resistance to 300℃.

- Higher Chemical reistance.

- Stronger initial adhesion.

- PI core material

- Excellent ink stability

HP-160

- Maximum heat resistance to 300℃.

- Application temperature from room temp to 300℃.

- Exceptionally strong initial adhesion

- Excellent ink stability

HP-150N

- Maximum heat resistance to 350℃.

- Application temperature from room temp to 350℃.

- Strong initial adhesion.

- Excellent ink stability

HP-350N

- Maximum heat resistance to 600℃.

- Application temperature from room temp to 400℃.

- Excellent ink stability at higher application temperatures

HP-360

- Maximum heat resistance to 600℃.

- Stronger adhesion over 500℃

- Application temperature from room temp to 400℃.

- Excellent ink stability

HP-380N+

- Maximum heat resistance to 600℃.

- Strong initial adhesion.

- Thiner, softer AL core for application on rough surfaces

- Unique 2 layer adhesive

- Excellent ink stability

HP-800A

- Maximum heat resistance to 800℃.

- Strong initial adhesion.

- Unique 2 layer adhesive.

HP-800C

- Maximum heat resistance to 800℃.

- Application temperature from room temp to 400℃.

HP-CBR CX2

- Maximum heat resistance to 1200℃.

- High flexibility

- After baking process, label becomes integrated with substrate surface

- Good durability against scratching, pickling, impact, and multiple heat cycles.

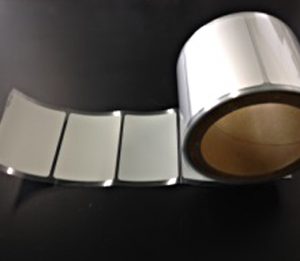

HP-CBR HB

- Maximum heat resistance to 1200℃.

- Good scanability after annealing in non-Oxygen atmosphere.

- High flexibility

- After baking process, label becomes integrated with substrate surface

- Good durability against scratching, pickling, impact, and multiple heat cycles.

Applications

Product identification and traceability is greatly improved when utilizing barcodes in the system.

HEATPROOF labels can be used in the annealing, homogenizing, reflow, and other high temperature processes.

Installation example

Steel

Annealing process management for cold coil

Electronics

Reflow process management